✔️ Spice manufacturing units

✔️ Food processing industries

✔️ Export-oriented spice production businesses

✔️ Ayurvedic and herbal product manufacturers

✔️ Small and medium-scale spice entrepreneurs

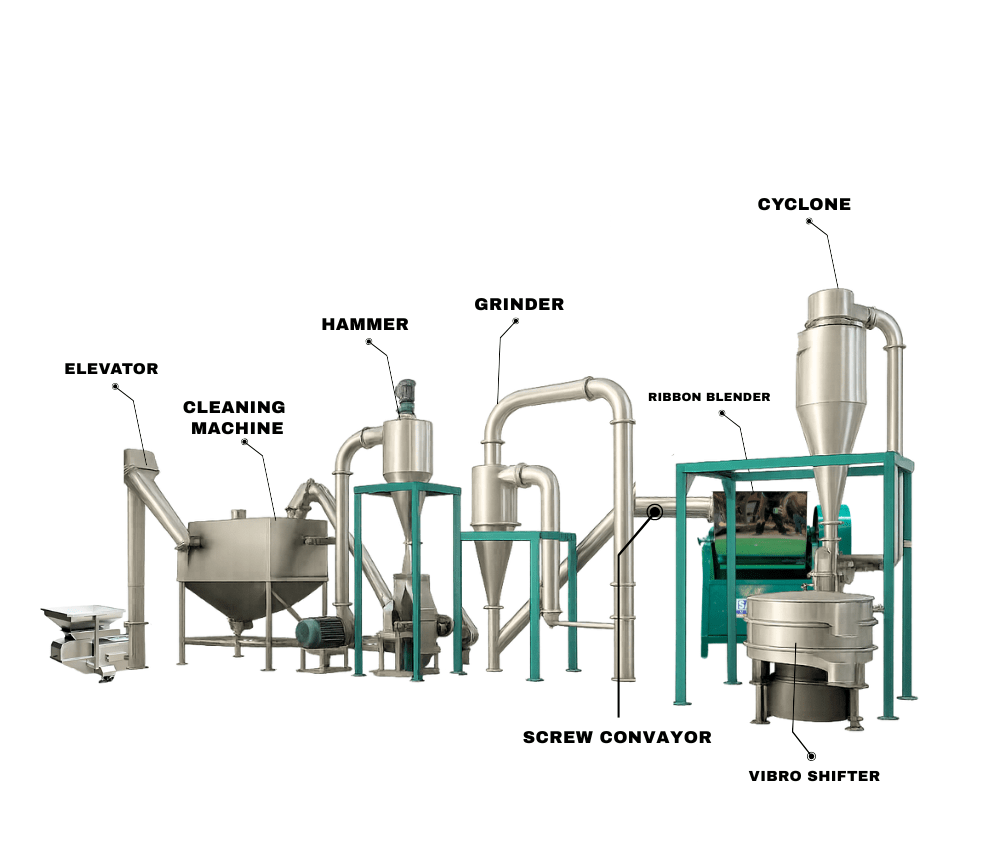

Samtek Machinery offers a state-of-the-art Automatic Spice Plant, designed for efficient and high-quality spice grinding, blending, and packaging. Our advanced plant is engineered to handle a wide range of spices, including turmeric, chili, coriander, cumin, black pepper, cardamom, cloves, and more. With cutting-edge automation and precision grinding technology, our plant ensures uniform particle size, rich aroma retention, and maximum flavor extraction.

Designed for small, medium, and large-scale spice processing industries, our fully automated system significantly reduces manual labor, improves hygiene, and enhances production efficiency. Whether you’re processing whole spices into fine powder or blending multiple ingredients for spice mixes, Samtek Machinery’s Automatic Spice Plant is the perfect solution for consistent quality and high output.

✅ Fully Automated Processing – From raw material cleaning to grinding, blending, and packaging, our system operates seamlessly with minimal human intervention.

✅ High-Performance Grinding Technology – Equipped with hammer mills, impact pulverizers, and pin mills for precise and uniform grinding, ensuring fine powder consistency.

✅ Multi-Stage Cleaning System – Includes vibratory separators, de-stoners, magnetic separators, and air classifiers to remove impurities and foreign particles before processing.

✅ Aroma & Flavor Retention – Uses low-heat grinding technology to prevent loss of natural oils, essential flavors, and nutrients in spices.

✅ Energy-Efficient & Cost-Effective – Optimized for low power consumption, reducing operational costs without compromising productivity.

✅ Dust-Free & Hygienic Processing – Advanced dust collection and cyclone separator systems keep the production environment clean and compliant with food safety standards.

✅ Customizable Configurations – Available in different capacities and specifications to cater to specific processing needs, from small-scale businesses to industrial spice production.

✅ User-Friendly & Low Maintenance – Easy-to-operate control panel with automated monitoring, ensuring smooth operation and quick troubleshooting.

Samtek Machinery, we understand the importance of quality, efficiency, and hygiene in spice processing. Our Automatic Spice Processing Plant is built with advanced technology and precision engineering, ensuring consistent quality, maximum output, and low operational costs. With customized solutions to fit different business needs, we provide a complete spice processing solution from cleaning to final packaging.

© 2023 Samtak Engineeing And GIS Solutions Pvt. Ltd.