✔️ Commercial besan manufacturing units

✔️ Food processing industries

✔️ Sweet and snack production businesses

✔️ Medium and large-scale flour mills

✔️ Small-scale entrepreneurs expanding into besan production

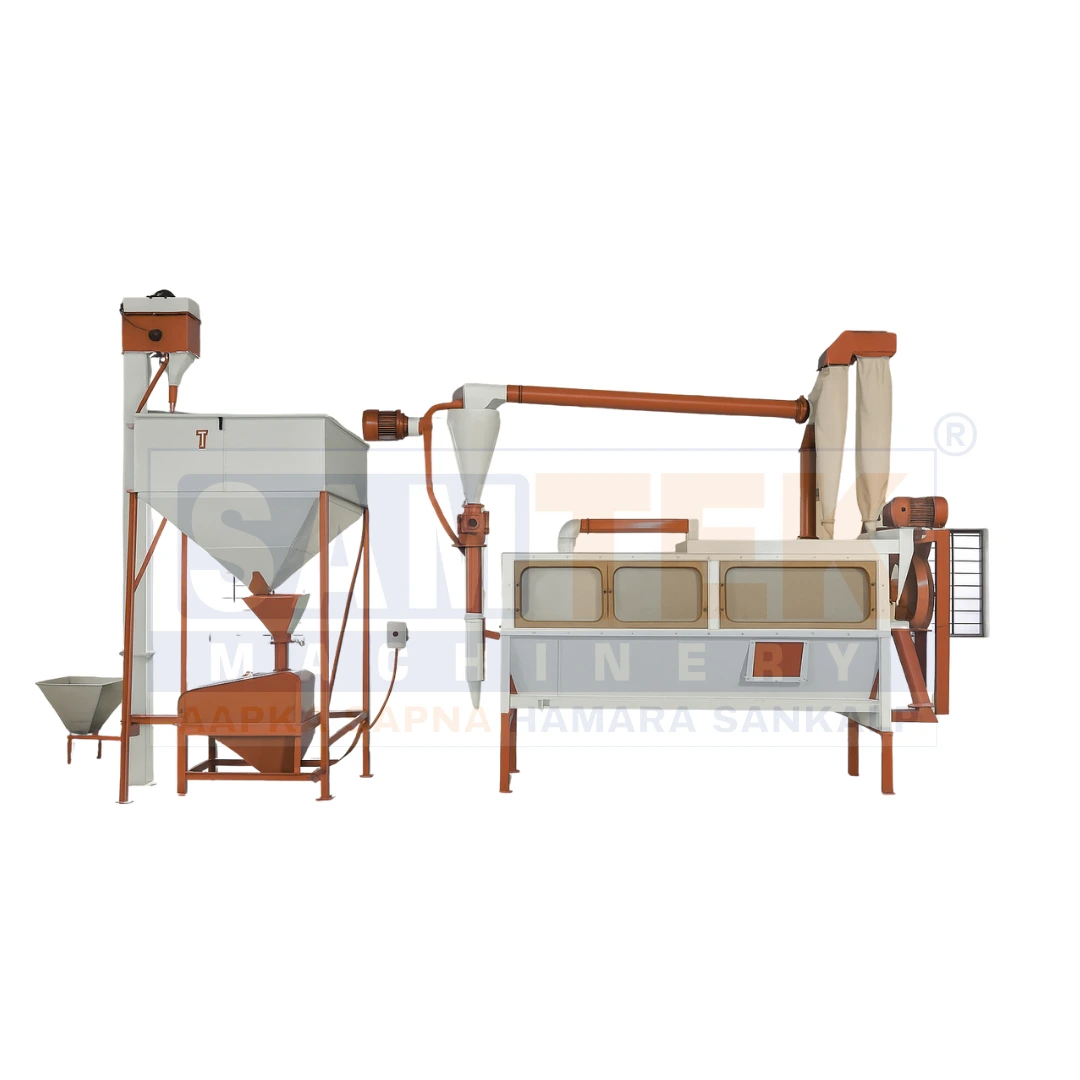

Samtek Machinery offers a state-of-the-art Fully Automatic Besan Plant, designed for seamless and high-quality gram flour (besan) production. Our advanced plant is engineered to process chana dal (chickpeas) into fine, pure, and high-grade besan with minimal human intervention. Featuring cutting-edge automation, precision grinding technology, and multi-stage processing, our besan plant ensures consistent flour quality, enhanced productivity, and energy efficiency.

Ideal for commercial besan production businesses, food processing industries, and medium to large-scale flour mills, our plant is built to handle high-capacity production while maintaining superior hygiene standards. With a fully automated system, businesses can significantly reduce labor costs, improve output, and maintain uniform product quality.

✅ Fully Automated Processing – The entire production process, from raw material cleaning to grinding, sieving, and packaging, is automated for maximum efficiency.

✅ Multi-Stage Cleaning System – Includes vibratory separators, de-stoners, magnetic separators, and air classifiers to remove impurities, ensuring clean and hygienic flour.

✅ High-Performance Grinding Technology – Equipped with impact pulverizers, hammer mills, and roller mills, ensuring fine and uniform besan particle size.

✅ Energy-Efficient Operation – Designed with low power consumption technology, reducing operational costs while maintaining high output.

✅ Advanced Sieving & Blending System – Ensures the final besan product meets the required mesh size and consistency standards.

✅ Dust-Free & Hygienic Processing – Features advanced dust control systems to maintain a clean production environment and comply with food safety regulations.

✅ Customizable Capacity – Available in various production capacities, suitable for small, medium, and large-scale operations.

✅ User-Friendly Interface – Automated control panels with real-time monitoring enable smooth operation, troubleshooting, and maintenance.

Samtek Machinery, we specialize in manufacturing high-performance, cost-effective, and durable food processing solutions. Our Fully Automatic Besan Plant is designed to provide maximum yield, superior product quality, and reduced wastage. With advanced automation, precision engineering, and user-friendly operation, our besan mills help businesses enhance efficiency and profitability.

© 2023 Samtak Engineeing And GIS Solutions Private Limited